OEM/ODM Factory Wear-Resistant Steel Plate - China Hot sale NM360.NM400.NM450 NM500 Wear Resistant Steel Plate – Bangrun

OEM/ODM Factory Wear-Resistant Steel Plate - China Hot sale NM360.NM400.NM450 NM500 Wear Resistant Steel Plate – Bangrun Detail:

Product Description

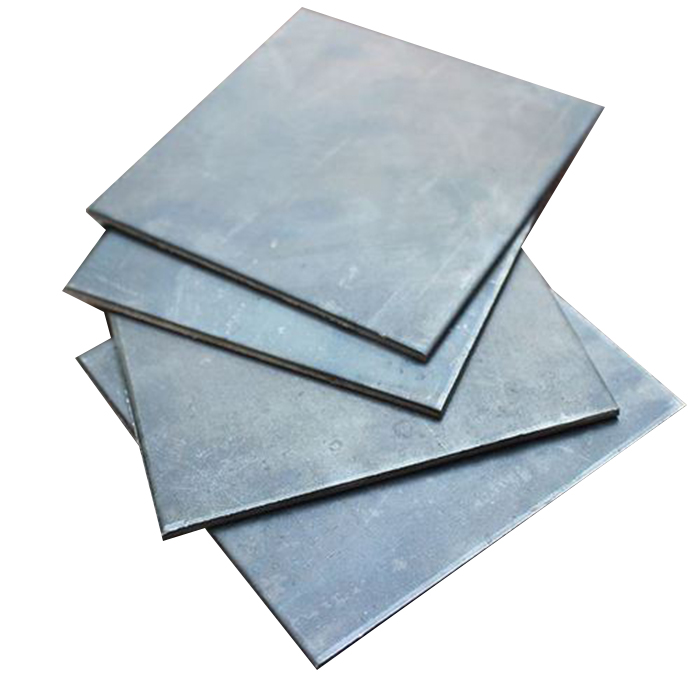

The wear-resistant steel plate is composed of a low-carbon steel plate and an alloy wear-resistant layer. The alloy wear-resistant layer is generally 1/3 to 1/2 of the total thickness. When working, the matrix provides comprehensive properties such as strength, toughness and plasticity against external forces, and the alloy wear-resistant layer provides wear resistance that meets the requirements of specified working conditions.

There is a metallurgical bond between the wear-resistant steel plate alloy wear-resistant layer and the substrate. Through special equipment and automatic welding process, the high-hardness self-shielding alloy welding wire is uniformly welded on the substrate. The composite layer has one to two layers or even multiple layers. During the composite process, due to the different shrinkage ratio of the alloy, uniform transverse cracks appear. It is a remarkable feature of wear-resistant steel plate .

Application

1. Thermal power plant: the cylinder lining of the medium-speed coal mill, the shell of the fan impeller, the inlet flue of the dust collector, the ash duct, the lining of the bucket turbine, the connecting pipe of the separator, the lining of the coal crusher Plate, liner of coal hopper and crusher, burner of burner, liner of coal hopper and funnel, support tile of air preheater, guide vane of separator. The steel used in the above machines can all be processed with wear-resistant steel plates.

2. Coal yard: the lining of the feeding trough and hopper, the lining of the hopper, the blades of the fan, the bottom plate of the pusher, the liner of the cyclone dust collector, the coke guide, the lining of the ball mill, the drill stabilizer, the spiral The feeder bell and its base, the inner lining of the bucket of the kneader, the ring feeder, and the bottom plate of the dump truck. Because the plate is to be used in the coal yard, there are certain requirements for the corrosion resistance and wear resistance of the steel plate. Moreover, the use environment of the coal yard is relatively more complicated, and this kind of material needs to be used better. Wear-resistant steel plate processing, such as EH series wear-resistant steel plate of Japan JFE and DILLIDUR wear-resistant steel plate of Dillingen, Germany.

3. Cement plant: chute lining, end bushing, cyclone dust collector, powder separator blades and guide blades, fan blades and lining, recycling bucket lining, screw conveyor bottom plate, piping components, frit cooling plate Lining, conveying trough lining board. These parts also require wear-resistant steel plates with better wear resistance and corrosion resistance, which requires a wear-resistant steel plate treated with a special process.

4. Loading machinery: unloading mill chain plate, hopper lining plate, grab blade plate, automatic dump truck dump board, dump truck body. This requires wear-resistant steel plates with extremely high wear resistance and hardness. It is recommended to use JFE-EH-C500, JFE-EH-C550, DILLIDUR 500V, DILLIDUR 550V and other materials, and the thickness of the wear-resistant steel plate is 25-45MM.

Mining machinery: linings, blades, conveyor linings and baffles of mineral materials and stone crushers. Such parts require extremely high wear resistance and can be processed with wear-resistant steel plates with a thickness of 10-30mm, such as JFE-EH-C500, JFE-EH-C550, DILLIDUR 500V, DILLIDUR 550V and other materials.

6. Construction machinery: cement pusher tooth plate, concrete mixing tower, mixer lining plate, dust collector lining plate, brick machine mold plate. Because its parts are easy to wear, it is recommended to use wear-resistant steel plates made of JFE-EH-C340, JFE-EH-C400, DILLIDUR 400V and other materials with a thickness of 10-30mm.

7. Construction machinery: loaders, bulldozers, excavator bucket plates, side blade plates, bucket bottom plates, blades, rotary drilling rig drill rods. This type of machinery requires wear-resistant steel plates that are particularly strong and wear-resistant, and can be made of JFE-EH-C500, JFE-EH-C550, DILLIDUR 500V, DILLIDUR 550V and other materials, with a thickness of 20-60mm. Grinding steel plate processing.

8. Metallurgical machinery: iron ore sintering machine, conveying elbow, iron ore sintering machine liner, scraper liner. Because this kind of machinery not only needs high temperature resistance, but also requires the use of extremely hard wear-resistant steel plate processing.

9. The industry applications of wear-resistant steel plates usually include the above eight industries, but there are more industries that also use wear-resistant steel plates. Wear-resistant steel plates can be used in parts, bearing structural parts, railway wheel structural parts, rolls, etc.

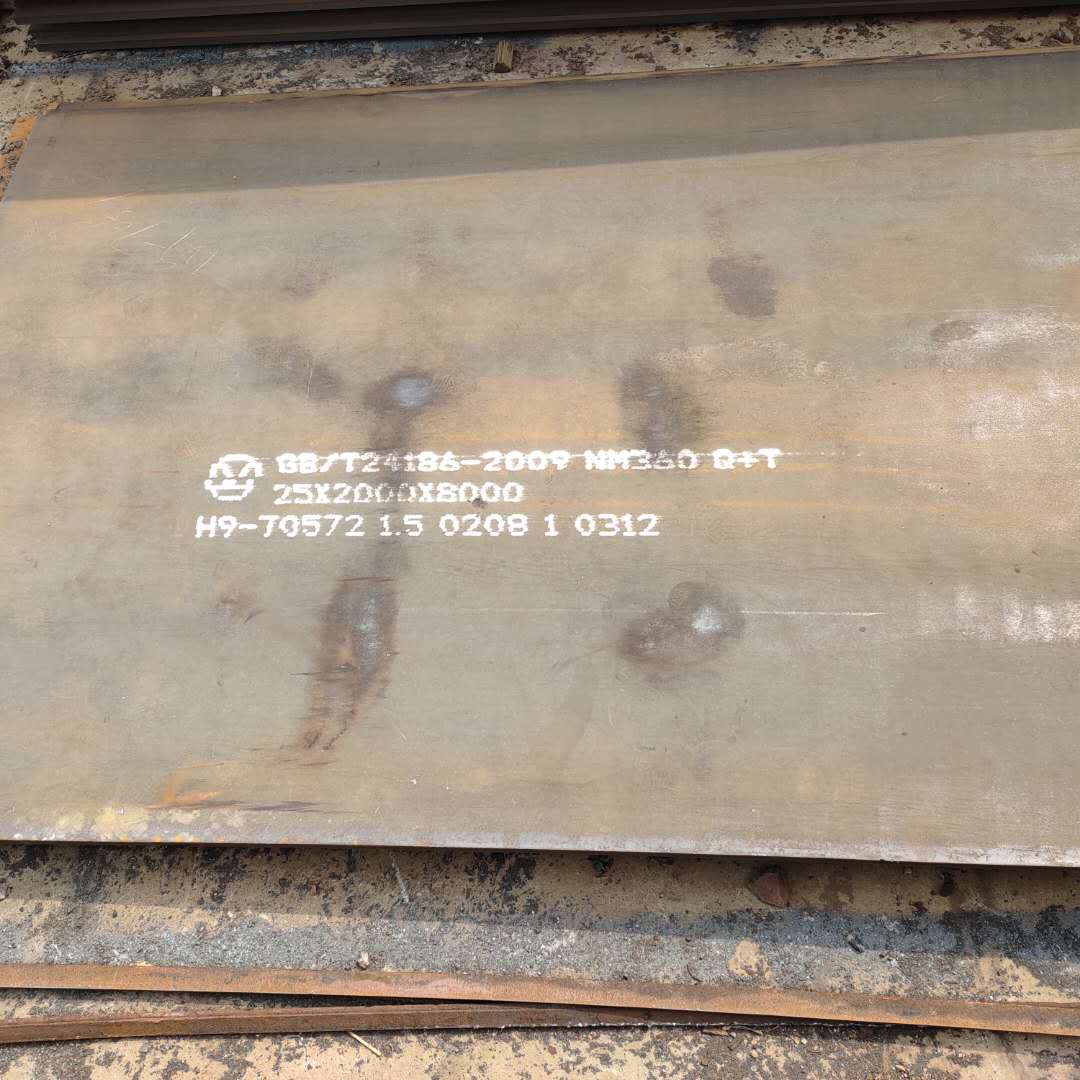

Standards and parameters

| Standard | Grade | |

| China | NM360.NM400.NM450 NM500 | |

| Sweden | HARDOX400,HARDOXX450.HARDOX500.HARDOX600,SB-50,SB-45 | |

| Germany | XAR400. XAR450. XAR500.XAR600. Dilidur400,illidur500 | |

| Belgium | QUARD400,QUARD450.QUARD500 | |

| France | FORA400, FORA500, Creusabro4800, Creusabro8000 | |

| Japan | JFE-EH360 JFE-EH400 JFE-EH500 WELHARD400 WEL-HARD500 | |

| MN13 High manganese wear-resistant steel plate : The manganese content is 130%,which is about 10times that of ordinary wear-resistant steel,and the price is relatively high. | ||

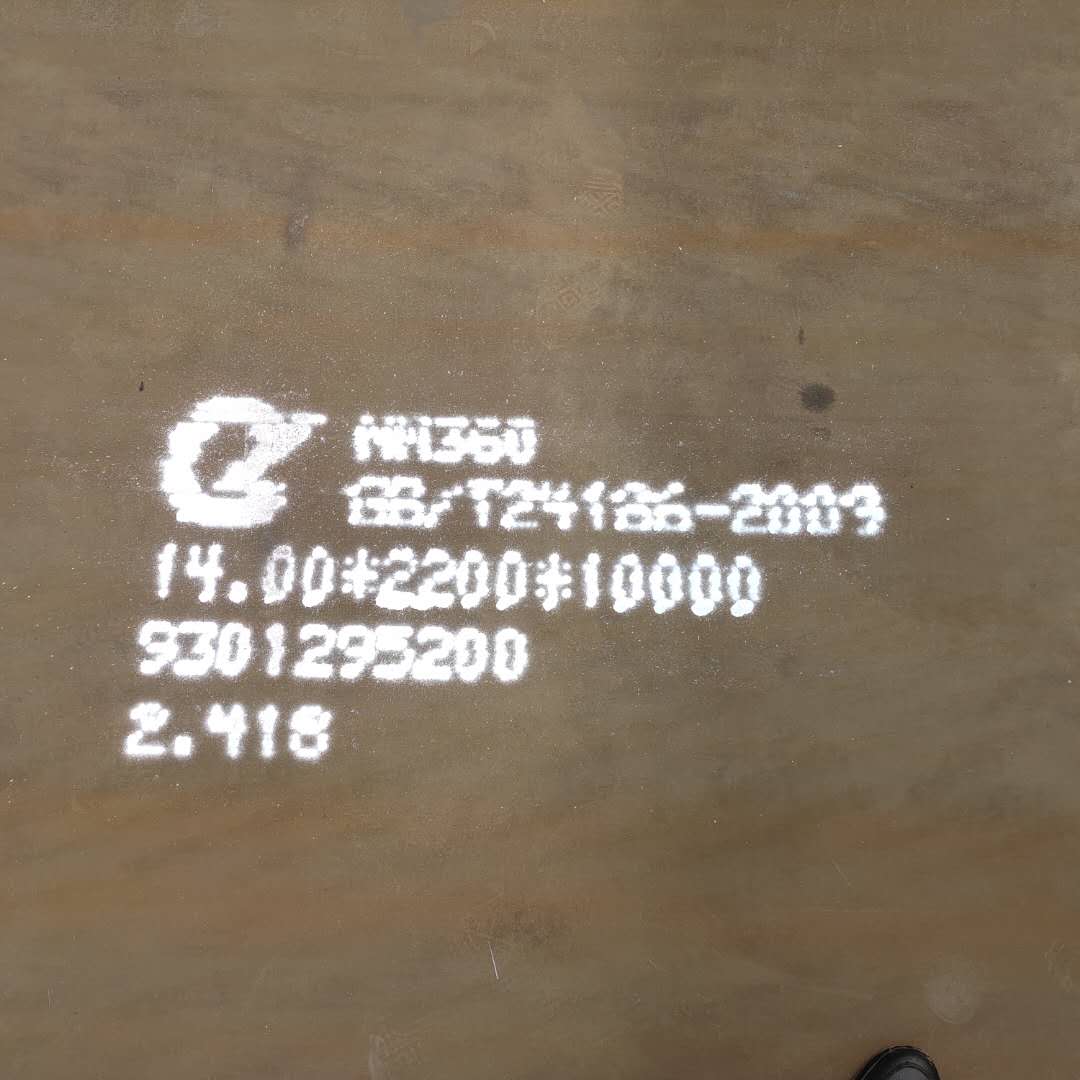

| Size specifications(mm) | ||

| Thickness | 3-250mmCommon size:8/10/12/14/16/18/20/25/30/40/50/60 | |

| Width | 1050-2500mmCommon size:2000/2200mm | |

| Length | 3000-12000mm | |

| Common size | 8000/10000/12000 | |

Note: we provide customize service, all the steel tube will according your design to produce it.

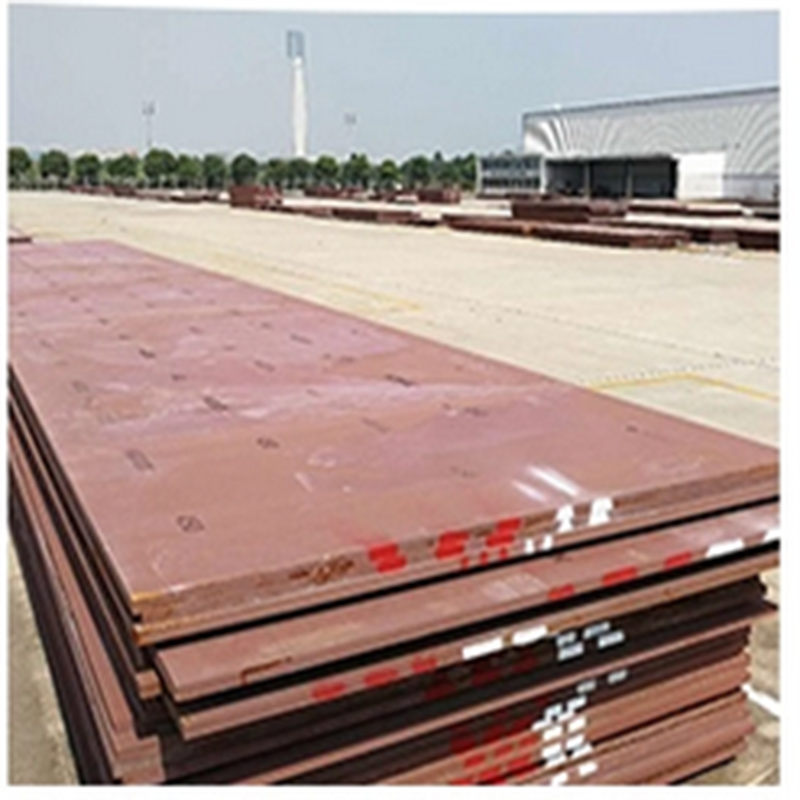

Product detail pictures:

Related Product Guide:

Trustworthy good quality and excellent credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality first, buyer supreme" for OEM/ODM Factory Wear-Resistant Steel Plate - China Hot sale NM360.NM400.NM450 NM500 Wear Resistant Steel Plate – Bangrun , The product will supply to all over the world, such as: Liberia, Paris, Rome, To keep the leading position in our industry, we never stop challenging the limitation in all aspects to create the ideal products. In his way, We can enrich our life style and promote a better living environment for the global community.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!