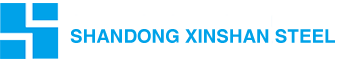

China High Quality Galvanized Steel Pipes For Construction Works

The hot-dip galvanized pipe is to make the molten metal react with the iron matrix to produce an alloy layer, so that the matrix and the coating are combined. Hot-dip galvanizing is to pickle the steel pipe first. In order to remove the iron oxide on the surface of the steel pipe, after the pickling, it is cleaned in a tank with ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to In the hot dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. The hot-dip galvanized steel pipe matrix undergoes a complex physical and chemical reaction with the molten plating solution to form a corrosion-resistant zinc-iron alloy layer with a compact structure. The alloy layer is integrated with the pure zinc layer and the steel pipe matrix, so its corrosion resistance is strong.

Cold galvanized pipe is electro-galvanized, and the amount of galvanizing is very small, only 10-50g/m2, and its corrosion resistance is much worse than that of hot-dip galvanized pipe. Most of the regular galvanized pipe manufacturers do not use electro-galvanization (cold plating) in order to ensure the quality. Only those small enterprises with small scale and outdated equipment use electro-galvanization, and of course their prices are relatively cheaper. The Ministry of Construction has officially announced that cold-galvanized pipes with backward technology should be eliminated, and cold-galvanized pipes are not allowed to be used as water and gas pipes. The galvanized layer of cold galvanized steel pipe is an electroplated layer, and the zinc layer is separated from the steel pipe matrix. The zinc layer is thin, and the zinc layer simply adheres to the steel pipe substrate and is easy to fall off. Therefore, its corrosion resistance is poor. In newly-built houses, it is prohibited to use cold-galvanized steel pipes as water supply pipes.

National standards and size standards for galvanized pipes

GB/T3091-2015 Welded steel pipe for low pressure fluid transportation

GB/T13793-2016 Straight Seam Electric Welded Steel Pipe

GB/T21835-2008 welded steel pipe size and unit length weight

Hot-dip galvanized steel pipes are widely used in construction, machinery, coal mines, chemicals, electric power, railway vehicles, automobile industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery, greenhouse construction and other manufacturing industries.

Galvanized steel pipes are welded steel pipes with a hot-dip galvanized or electro-galvanized layer on the surface. Galvanizing can increase the corrosion resistance of the steel pipe and prolong the service life. Galvanized pipe has a wide range of uses. In addition to line pipes for conveying water, gas, oil and other general low-pressure fluids, it is also used as oil well pipes and oil pipes in the petroleum industry, especially offshore oilfields, as well as oil heaters and condensation for chemical coking equipment. Pipes for coolers, coal-distilled wash oil exchangers, pipe piles for trestle bridges, and pipes for support frames in mine tunnels, etc.